The A3 is first and foremost a tool for identifying root causes to deep challenges and achieving consensus on what exactly those problems are and how to remedy them. The process was pioneered by Toyota to document problems with their production process. Anyone at Toyota can initiate the process and they do it for almost all problems they encounter. To capture their analysis, they use the largest sheet of paper that fit into a copy machine, the A3 or Tabloid (two 8.5x11 sheets side-by-side.)

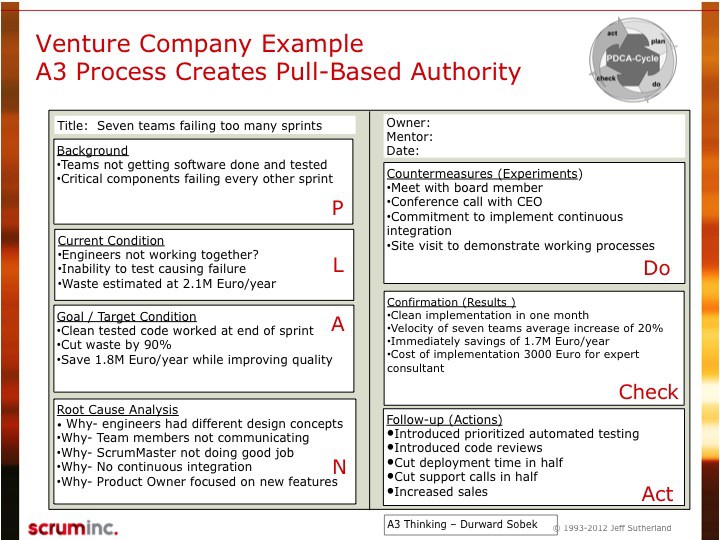

The A3 process is based on the Plan, Do, Check, Act, or PDCA Cycle. To initiate the A3 process all the stakeholders should gather. An A3 is meant to simplify complex problems, so using just one large sheet of paper follow the example in the tab below. The title should be something catchy so it is easy to remember and to refer to. The owner is the person who is responsible for ushering the process through to its end and the mentor is typically a high-ranking executive who can help implement the actions that result from the process.

With the background established, the discussion moves on to establishing the current conditions. This will be a list of symptoms like decreased Velocity or bad morale. It is important to make sure that the group is able to include some Metrics in this cell. Loss of revenue is always helpful because it gets management’s attention but any number of metrics will do. The important part is that they are precise and measurable.

Next, the group should decide on what the conditions will be if the problem is solved. The target conditions are similar to an Acceptance Test or Definition of Done for a Product Backlog Item. Metrics are helpful here as well. The idea is to provide a somewhat objective condition in which all stakeholders could feel the problem was solved. It is important to have a well-defined target condition because it will help align all stakeholders around a common vision.

The last part of the planning phase is root cause analysis (see video) and is really the core of the A3. Establishing the problem and what life will be like after the problem is solved is relatively easy, agreeing on what the root causes are may involve some uncomfortable truths.

It sounds very high minded, but good root cause analysis actually requires channeling your inner five-year old. The technique used is called the Five Whys. Basically, the group needs to start with the most obvious problem and ask why. Here is an example:

Sprints are failing. “Why?” A: People think that the Team is lazy. “Why?” A: Because morale is low. “Why?” A: The Team is getting mixed messages from the Product Owner. “Why?” A: The Product Owner is getting conflicting orders from two managers. “Why?” A: The organization incentivizes competition rather than cooperation.

The point of the exercise is to get at least five layers deep into any problem. Five layers is a general rule of thumb. Root causes can be found three or seven layers deep. It is really important to invest a lot of time here. Often the stakeholders think they have arrived at a few root causes only to have to repeat the process later. Another good rule of thumb is that once the group thinks its discovered the root causes, they should then put in again as much time as they’ve just spent. It’s important to be exhaustive. (There are other root cause analysis techniques. A variety can be found here.)

There will likely be multiple root causes to a problem. In the above example, the Product Owner role has broken down, managers are probably talking to the team outside of their scope and the organization’s incentives are flawed.

A root cause is highly dependent upon the organization, the developmental process and, most importantly, the people involved so coming up with an example is difficult. However, there are a few signs. First, a root cause will probably resonate with most stakeholders. Root causes also tend to be actionable, meaning that the group will have an idea how to solve the specific challenge. And, a root cause will have a certain amount of detail. In the above example, “people think the Team is lazy” doesn’t have any granularity. Further inquiry helped pinpoint a more detailed root cause.

Typically, it is a good idea to implement one countermeasure at a time. Given the nature of complex-adaptive systems, a change to one part of the system could ripple throughout the organization, changing the overall issue. If it turns out the countermeasure doesn’t work, or does work and doesn’t change the problem, the group can move onto the next root cause and its countermeasure. Or, it may be that solving the first root cause reveals that the problem resides in another part of the organization. The A3 is a living document so the group should continually update it as conditions change.

Countermeasures, like root causes are typically specific to the organization and can’t be proscribed based on the problem alone. If the group is unable to settle on a solution, it is probably outside of the organization’s power to solve. It could be that there is no demand for a certain product or feature. If this is the case, it may be time for leadership to realize they need a different vision.

If the countermeasure worked, great, if it had an effect on the current conditions and moved the Team closer to the target condition, it may be that multiple countermeasures are necessary to achieve the target condition. If there is no effect move on to the next countermeasure for that root cause or move onto the next root cause and try its countermeasure.

Hard Truths

When an A3 fails it is usually because the group didn’t delve deep enough into the problem or that the problem was beyond the ability of the team to solve or recognize. Solving the root cause can be the end result of a successful A3. However, that’s not always the case. A successful A3 can show that the root cause is beyond the ability of the organization to change like in the above example where there wasn’t enough market demand for the product. A good A3 can reveal deep challenges within the organization like conflicting core values, poor leadership or a critical lack of resources. The A3 isn’t a silver bullet; rather it’s a tool to bring transparency to dysfunction. How the stakeholders handle the dysfunction is their responsibility.

Paper:

A3 PROBLEM SOLVING TOOL: Jakobson Lean as Scrum Troubleshooter

The Scrum Pattern Language of Programming codifies well known Agile practices that have been successfully implemented many times.

The post A3 – Root Cause Analysis appeared first on Scrum Inc..